Chip Carving – Cutting Triangle and Square Chips

![]() In today’s free online Chip Carving Seminar by Lora Irish, we look at the wood carving cuts used to create triangle and square chips in your chip carving patterns.

In today’s free online Chip Carving Seminar by Lora Irish, we look at the wood carving cuts used to create triangle and square chips in your chip carving patterns.

Chip Carving Seminar by Lora Irish

Chip Carving Seminar

Chip Carving Seminar

Chip Carving Supplies

Chip Carving Graphed Patterns

Chip Carving Hand Positions and Grips

Chip Carving – Triangles and Square Chips

Chip Carving – Straight-Wall Chips

Chip Caved Game and Chess Board

Chip Carving Sampler Pattern Layout

Chip Carving Common Mistakes

Chip Carved Shortbread Cookies

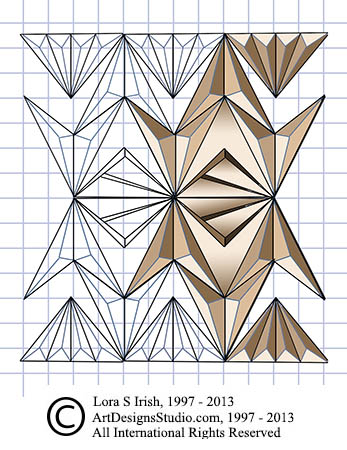

Triangle Chip Patterns

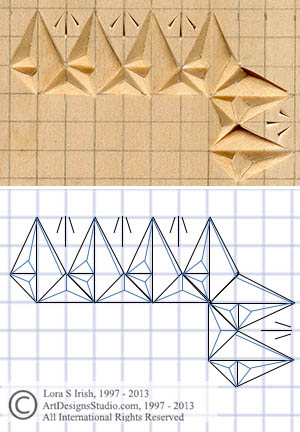

The triangle and square are the primary shapes in most chip carving patterns. In the sample, right, you will see six different ways you can cut one 3×2 grid diamond motif using these two geometric units. Any chip carving pattern can easily be altered by simply dividing the triangles in your pattern into smaller triangles.

In my chip carving patterns the outer edge of any chip unit is shown in black, the inner liner shown in blue represent the individual cuts that make up that shape.

In row one the diamond is cut in four separate chip cuts to create one deep well at the center point of the diamond. The second row divides the diamond shape into two individual triangle chips and does row three. By the fourth row you can see that this same diamond shape can also be cut using four distinct triangle chip units.

By using just these six sample diamonds you can create multiple chip carved borders or motifs.

Three-Sided Triangle Chip

Three-Sided Triangle Chip

The three-sided triangle chip is made with three cuts, turning the board with each new cut. This releases a small chip of wood, leaving an inverted pyramid shape in the board.

The angle at which the knife approaches the wood determines the depth of the chip cut. A low angle makes a shallow chip, a steep angle cuts a deep chip.

CUT 1

CUT 1

The first cut is made by placing the point of the blade along one side of the triangle, holding the blade at a 45 degree angle to to the wood.

The knife is pushed in to the wood until the blade edge has cut along the full length of that leg. For large chip triangles the knife blade is pulled along the pattern line.

CUT 2

CUT 2

Turn the wood to bring the next leg of the triangle into position for cutting. Lay the point of the knife at the beginning point of the next leg. Push the knife into the wood until the entire leg is cut.

CUT 3

CUT 3

Turn the wood to bring the last leg of the triangle into position for cutting. Lay the point of the knife into the point at the end of the last cut line which should be at the beginning of the leg. Push the knife into to the wood until the entire length is cut.

Square and Rectangle Chips

Square and Rectangle Chips

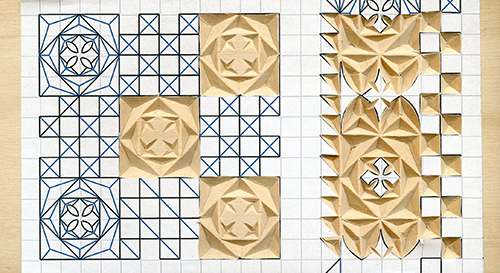

Square and rectangle chips are created with four angled cuts, similar to the triangle chip. This pattern of chip is excellent to add small accents to a larger designs and for large area fill patterns.

CUT 1 – 4

CUT 1 – 4

A square chip is worked exactly as a triangular chip, cutting each side of the square with the blade point angled towards the center point of the well. Cut along one side of the square, then turn the board to cut the next side. When all four cuts have been made a small pyramid shaped chip will be released. Rectangular patterns will have a long, centrally placed line in the well. This long line parallels the long sides of the rectangle. Rectangle chips are commonly used in chip carved lettering.

Cutting Adjacent Triangle and Square Chips

Cutting Adjacent Triangle and Square Chips

Most chips that you cut will share one or more sides with another chip. Begin a motif with touching or shared-side chips by working the inside chip first, working each series of new chips out from the center. In the photo sample, right, one row of triangle chips touch the inside square of the motif. The second, outer row of triangles touch the outer square lines of the motif.

![]() Work each new chip by cutting the trapped angle of the chip along one shared-side line, working from the inside point towards the outside point of the triangle. The second cut is made from the same inside trapped angle out towards the outer point of the line on the second side of the trapped angle.

Work each new chip by cutting the trapped angle of the chip along one shared-side line, working from the inside point towards the outside point of the triangle. The second cut is made from the same inside trapped angle out towards the outer point of the line on the second side of the trapped angle.

![]() The third cut is made on the free side of the triangle, releasing the chip. Working form the trapped angle avoids the inner-trapped point of the chip from breaking out.

The third cut is made on the free side of the triangle, releasing the chip. Working form the trapped angle avoids the inner-trapped point of the chip from breaking out.

Today’s Free Chip Carving Practice Pattern

Today’s Free Chip Carving Practice Pattern

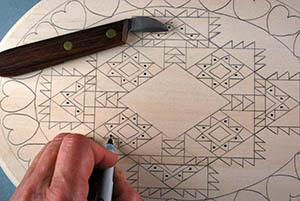

Please click on the image to the right for a full-sized printable chip carving pattern to use for your practice board. You may either transfer your chip carving pattern using a pencil grid or by using removable spray adhesive. Remember chip carving takes practice to create clean, smooth, even sides to each chip. So print several copies.

Chip Carving – Cutting Triangle and Square Chips Read More »