Setting Up Your Scroll Saw

Where and how you set up your scroll saw is extremely important to the quality of cutting your can do in your new craft. We will take a qick look at several options to placing your saw into the most comfortable, accurate cutting position as possible.

Where and how you set up your scroll saw is extremely important to the quality of cutting your can do in your new craft. We will take a qick look at several options to placing your saw into the most comfortable, accurate cutting position as possible.

Cross-Crafting Seminar Introduction

Cross-Crafting Seminar Supply List

Cross-Crafting Seminar Free Patterns

Cross-Crafting Seminar, Scroll Saw Basics

Cross-Crafting Seminar, Setting Up Your Scroll Saw

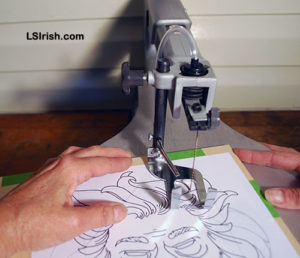

Cross-Crafting Seminar, Scroll Sawing the Wood Spirit Face

Cross-Crafting Seminar, Wood Burning the Wood Spirit Face

Cross-Crafting Seminar, Colored Pencils for the Wood Spirit Face

I am lucky enough to have both a full-dedicated woodworking shop and a craft studio. My shop holds my table saw, drill press, band saw, as well as an extra-large work table where I can clamp, glue, and sand. The craft shop is where I work on my smaller projects as my wood carving and wood burning.

But, for right now, I am setting up my scroll saw on my back porch! Since the Ryobi 16″ Variable Speed Scroll Saw is quite portable I can store the tool in its shipping box in the studio when I am not using it, and then move it to the porch for those quick cuts or full-length projects.

The reason I am working off the back porch is because I have an old, hard-used dry sink that measures 38″ from the floor to the table top – a perfect height for me for scroll saw cutting. The base of the dry sink holds two shelves where I store several furniture clamps, my vise, and some of the woodworking tools that I need around the studio.

The reason I am working off the back porch is because I have an old, hard-used dry sink that measures 38″ from the floor to the table top – a perfect height for me for scroll saw cutting. The base of the dry sink holds two shelves where I store several furniture clamps, my vise, and some of the woodworking tools that I need around the studio.

For me, a standing position is the most comfortable for accurate cutting. The height of this dry sink lets me look into the saw blade area of the scroll saw at a 45 degree angle – perfect to see exactly where the blade is in the wood and to clearly see the cutting line on the pattern. Note position #2 in the photo.

A standard table is only 30″ tall at the top of the table. If you are in a standing position this puts your focus point directly on the wood. While you can see the pattern line clearly, this high angle obscures your view of the saw blades working edge. Note position #3 in the photo.

If you chose a sitting position using a kitchen chair, at a standard table your visual view is at a very low angle to the saw. You now see the full length of the saw blade but can barely see your wood or pattern line. Note position #1 in the photo.

There are several easy, inexpensive options for your new scroll saw table.

- You can purchase scroll saw stands that are heavy-weight metal made specifically to hold smaller-sized power tools. These are great if you have a full-dedicated workshop. The stands often are made to have a plywood table top which bolts to the stand. You can then bolt your scroll saw to the table top to reduce vibration.

- Check you have a local Habitat for Humanity ReStores your tall kitchen cabinets or bathroom cabinets at extremely reasonable prices. Again, you will need to create a table top, out of 5/8″ plywood which you bolt to the cabinet. If your kitchen cabinets are a bit short you can create a plywood box for the table top that brings your saw up to the perfect height for you.

- If you are using a regular table, studio table or kitchen table, which are only 30″ high, you may want to purchase a tall bar stool for just a few dollars at your local GoodWill. Since you can’t safely raise the height of your saw you can easily raise yourself to get that 45 degree view of the saw.

A few more considerations.

I find that I do need a wide foot print around my scroll saw as I work. I tend to move my body, re-position my stance left or right, as I move through the curves. So I work in an area where I have about 2′ to 3′ feet of clear space on either side of the scroll saw table.

Because of the amount of dust created by the saw I find that a good, heavily-textured floor mat gives me a firm stance on the floor. Saw dust can be quite slippery! A 4′ x 5′ bound-edged rug works well, but you can also purchase heavy rubber floor mats meant for shop use.

Be sure that your working table is firmly set on the floor. Shim the table legs or base if necessary to insecure you have a secure working space.

If your scroll saw is light-weight, does not have a heavy iron base, you will want to secure the saw directly to the table top. You can either bolt the scroll to the table as most scroll saws have holes pre-drilled in the base to permanently set the saw to its stand or table. You can also use furniture clamps to secure the saw base to the table.

Never set your scroll saw on an unclamped or unsecure surface to raise the level of the blade to a better visual view … don’t set it on a stack of scrap plywood, stack of books, or a cardboard box. Any of these ‘solutions’ can slide out from under the saw or simply colapse while the saw is running. Instead, if you need to raise the level of the saw, do so by raising the entire table or cabinet using a 2″ x 4″ frame bolted directly to the bottom of the table.

To reduce any excess vibration try setting your scroll saw on a non-skip kitchen matt before you clamp it to the table. These matts are very inexpensive security!